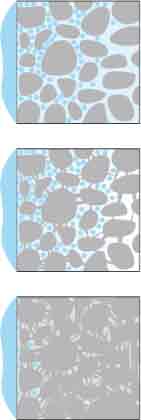

When a cement particle hydrates, it becomes a hard, solid mass. Crystalline waterproofing adds a second set of chemicals to the mixture that continue to react. So, like a cement particle, they continue to hydrate for the life of the structure. The end product is a non-soluble needle like structure — essentially, waterproof armor creating more sustainable concrete and preventing liquid from permeating its surface.

Any time that moisture comes in contact with the pores, capillaries, and shrinkage cracks of your structure, it becomes fuel to feed additional growth. Crystal formations seal up the cracks and protect these vulnerable spaces, becoming an integral part of your concrete in the process. Beyond keeping out water, they improve its overall strength and increase its lifespan, among other benefits. With just one simple solution, all your structure’s weak points are reinforced, plus an extra layer of protection against corrosive elements is added.